Redwing

Senior Member

- Joined

- Oct 15, 2021

- Threads

- 3

- Messages

- 134

- Reaction score

- 187

- Location

- Waco,Texas

- Vehicle(s)

- 2018 Honda Civic si coupe

- Thread starter

- #46

Apparently, I have too much time on my hands

I decided to estimate the forces and drag on the wing. Give thanks to @dt10g who got me into the weeds on this one.

Here is the link to the online calculator I used to approximate the forces generated on the wing at speed: https://www1.grc.nasa.gov/beginners-guide-to-aeronautics/foilsimstudent/ <-- Check it out its pretty cool.

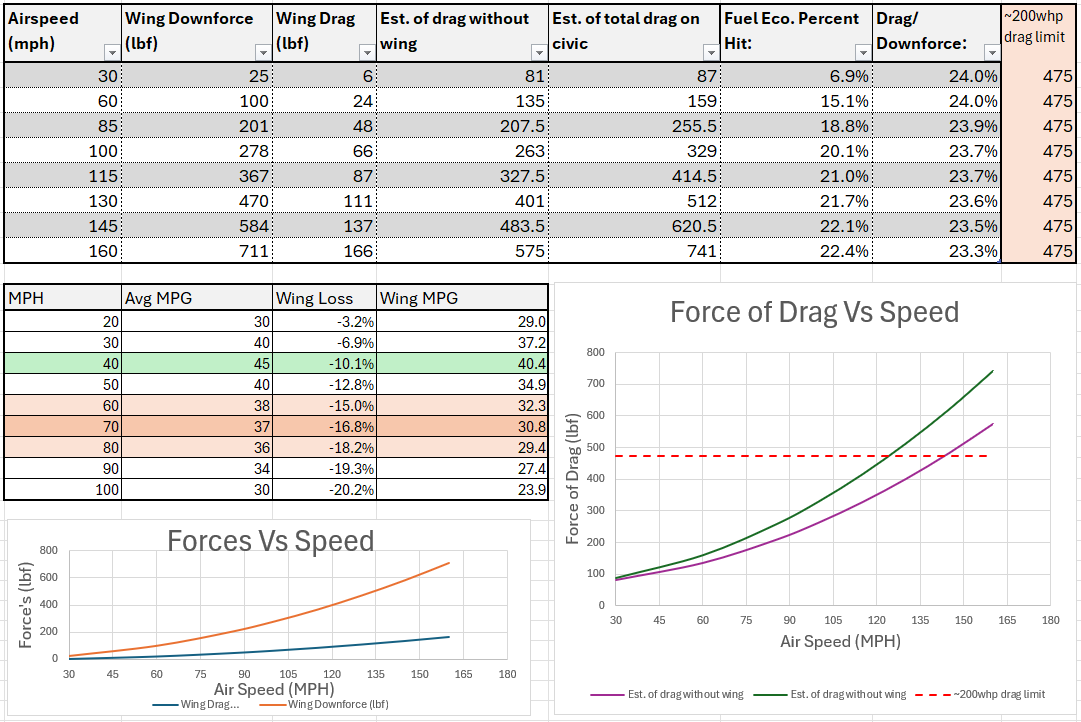

I then made a bunch of approximations and assumptions before coagulating them into a single excel spreadsheet:

**Important cavoite: from the assumptions I made, these numbers not at all trustworthy. Only after I actually test the wing will I find the true numbers, but this is a good start.**

I made what I hope is a decent safety margin on the maximum force generated by the wing. One of the primary assumptions was undisturbed airflow over a perfect airfoil. Hopefully this means the data that I took from the NASA simulation is decently higher than the actual wing performance. (Go check out their website they have a whole bunch of cool stuff)

So, let's take apart this data, shall we? What does it tell us?

The top speed I considered for this test was 160 mph based on it being around the theoretical top speed of 6th gear. At that speed the wing should make around 711 lbs of downward force and 166 lbs of drag. Thats almost 900 lbs of total force!

Now realistically, no-one is ever going to see 160 mph with this wing in a max downforce configuration. At top speed the wing is theoretically producing ~22% of the cars overall drag. I estimated the cars force of drag based on my personal top speed runs and an online calculator. With that data I estimated the theoretically top speed with the wing at my car's approximated 200 WHP. (Can you tell there were a lot of assumptions made yet?)

Here is the link I used to estimate the Civic's total drag force: https://www.e31.net/resistance.html

Now what do all my numbers mean in the real world? Well for starters your new top speed with this wing is going to be ~125 MPH. That drops the max downforces down to ~450 lbs. I believe this is manageable with proper trunk reinforcement, but time will tell. Actual testing will need to be had.

Also don't forget fuel economy is going to plumet. Based off the percentage of total vehicle drag, adding a high downforce wing will take ~15% of your fuel economy depending on how fast you drive.

What about performance? Well, all you AutoX junkies listen here! EXTRA GRIP IS WILL BE GOOD! The wing (although not super-efficient) will be very effective! At 60 MPH you can get up to 8% more grip on the rear tires! And it will look awesome while doing it!

Any questions? As always, let me know what yall think!

I decided to estimate the forces and drag on the wing. Give thanks to @dt10g who got me into the weeds on this one.

Here is the link to the online calculator I used to approximate the forces generated on the wing at speed: https://www1.grc.nasa.gov/beginners-guide-to-aeronautics/foilsimstudent/ <-- Check it out its pretty cool.

I then made a bunch of approximations and assumptions before coagulating them into a single excel spreadsheet:

**Important cavoite: from the assumptions I made, these numbers not at all trustworthy. Only after I actually test the wing will I find the true numbers, but this is a good start.**

I made what I hope is a decent safety margin on the maximum force generated by the wing. One of the primary assumptions was undisturbed airflow over a perfect airfoil. Hopefully this means the data that I took from the NASA simulation is decently higher than the actual wing performance. (Go check out their website they have a whole bunch of cool stuff)

So, let's take apart this data, shall we? What does it tell us?

The top speed I considered for this test was 160 mph based on it being around the theoretical top speed of 6th gear. At that speed the wing should make around 711 lbs of downward force and 166 lbs of drag. Thats almost 900 lbs of total force!

Now realistically, no-one is ever going to see 160 mph with this wing in a max downforce configuration. At top speed the wing is theoretically producing ~22% of the cars overall drag. I estimated the cars force of drag based on my personal top speed runs and an online calculator. With that data I estimated the theoretically top speed with the wing at my car's approximated 200 WHP. (Can you tell there were a lot of assumptions made yet?)

Here is the link I used to estimate the Civic's total drag force: https://www.e31.net/resistance.html

Now what do all my numbers mean in the real world? Well for starters your new top speed with this wing is going to be ~125 MPH. That drops the max downforces down to ~450 lbs. I believe this is manageable with proper trunk reinforcement, but time will tell. Actual testing will need to be had.

Also don't forget fuel economy is going to plumet. Based off the percentage of total vehicle drag, adding a high downforce wing will take ~15% of your fuel economy depending on how fast you drive.

What about performance? Well, all you AutoX junkies listen here! EXTRA GRIP IS WILL BE GOOD! The wing (although not super-efficient) will be very effective! At 60 MPH you can get up to 8% more grip on the rear tires! And it will look awesome while doing it!

Any questions? As always, let me know what yall think!

Last edited: